Provide customers with professional, franchised, dedicated and comprehensive services

To be one of the "Most Influential Enterprises in China's Adhesive Tape Industry"

Hotline:

+86-18082341928

To be one of the "Most Influential Enterprises in China's Adhesive Tape Industry"

Hotline:

+86-18082341928

Removable adhesive, also known as "traceless adhesive tape", is a stretchable Double-sided adhesive tape that is ideal for cell phone bonding in smartphones. Removable adhesive has a strong bond on the one hand and a removable feature on the other hand, providing the easiest and safest way for heavy work.

Removable adhesive is a removable removable tape that is the ideal solution to simplify the bonding and recycling process of electronic batteries. The battery in the electronic device can be firmly bonded. The most prominent feature is that it can be easily removed when the battery needs to be disassembled, leaving no residual glue, and the operation is convenient and quick.

1. Optimize the reworkability of the product: Since the assembly of electronic equipment has a certain probability of rework, the easy-adhesive tape can be easily removed without leaving residual glue. This saves time and money if parts need to be replaced during the assembly process. Although the adhesive tape can be easily removed, this range of products can be used for long-term fixation and provides excellent adhesion. Removable adhesive uses a unique adhesive material to separate the bonded surfaces by stretching the adhesive tape. For production line production, this feature is convenient for heavy work, fast and safe, reducing man-hours and not damaging the battery and the casing. For aftermarket, removable adhesive tape makes it easy and safe to replace batteries

2, excellent bonding properties: Removable adhesive on the one hand has a strong adhesion, excellent impact resistance, high peeling force and excellent push-out force, on the other hand also has removable properties.

3, Environment-friendly and in line with international standards: 1) With a uniquely formulated adhesive, Removable adhesive can be removed without residue after removal. The entire operation process does not require cleaning, no additional work hours, components can be reused immediately after disassembly, green Environment-friendly, cost savings; 2) At the same time, Removable adhesive is designed with EU regulations in mind.

Fixed battery, fixed lens, fixed parts, production aid, temporary fixing

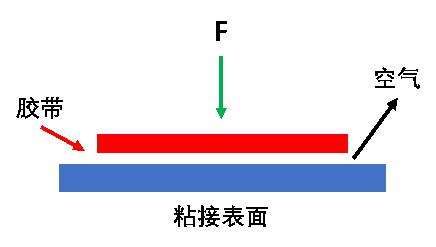

| 1, recommended bonding method: rolling method |

| Compared to the commonly used direct pressure method (Fig. 1), the rolling method (Fig. 2) can effectively avoid bubble problems. |

(Image 1)

(Image 2) |

| 2, bonding surface: flat bonding surface helps to improve the infiltration effect of Removable adhesive |

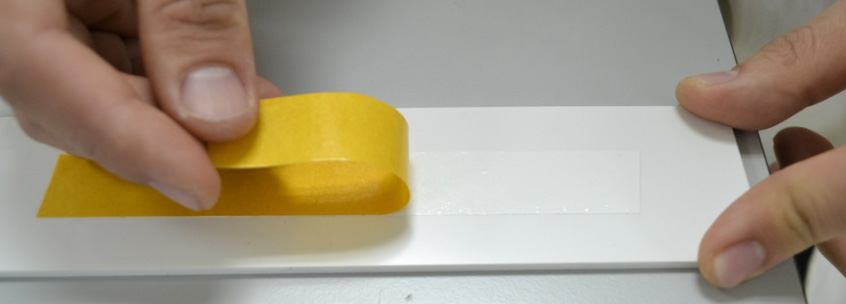

| 3, release paper peeling: When removing the release paper, it is recommended to slowly operate at 180° peel angle to avoid wrinkles or bubbles (Figure 3) |

(Image 3) |

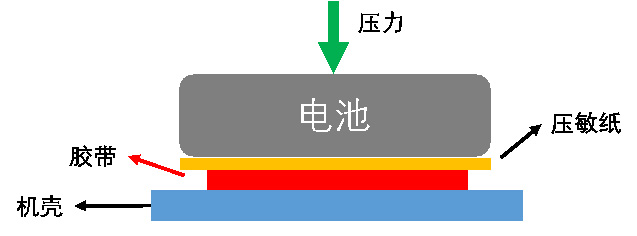

| 4. Stress test: |

| A uniform and effective pressure distribution increases the effective bond area between the battery and the casing, thereby improving the bonding. |

| The method of checking the pressure distribution before assembling the battery is as shown in (Figure 4): |

(Image 4) |

| After the pressure test, the pressure sensitive paper can achieve the following test results, which is the ideal pressure distribution state: |

(Image 5) |

| 5, remove the Removable adhesive |

| When removing, make sure that the force direction of the Removable adhesive is between 0-90°, and the angle at which the removal resistance is lowered should be ≤45°. (Figure 5) |

(Image 6) |

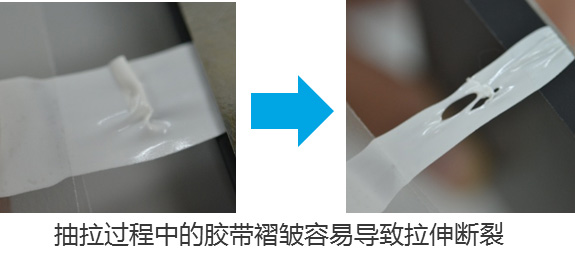

| Always avoid the wrinkles of the handle when you start pulling the adhesive tape handle to remove it, otherwise it will easily cause the adhesive tape to break (Figure 7). |

(Image 7) |

| Serial number | Model | Adhesive tape color | Thickness (mm) |

Adhesion (N/25mm) |

Retention (h) |

Elongation rate (%) |

Tensile strength (N/25mm) |

| 1 | YL501W/B | White/black | 0.10 | >15 | >24 | >600 | >18 |

| 2 | YL5013W/B | White/black | 0.13 | >18 | >24 | >600 | >22 |

| 3 | YL5015W/B | White/black | 0.15 | >22 | >24 | >600 | >26 |

| 4 | YL502W/B | White/black | 0.20 | >25 | >24 | >600 | >26 |

| 5 | YL5025W/B | White/black | 0.25 | >25 | >24 | >600 | >26 |

| 6 | YL504W/B | White/black | 0.40 | >25 | >24 | >600 | >26 |

| 7 | YL505W/B | White/black | 0.50 | >25 | >24 | >600 | >26 |

| ★ Note: The above results are representative values detected by the company according to the standard test method, not guaranteed values. | |||||||

Go

Top